Manufacturing and machine shop services

Flexible Manufacturing Systems (FMS)

As pioneers of manufacturing technology, we continue to invest in tools and equipment that keep us on the leading edge of our industry. With the use of flexible manufacturing systems (FMS) from Mazak and Makino, we can run far more machines with fewer operators, increase productivity and lean on automated accuracy.

Within each of our FMS, the initial setup of a part is retained in its entirety for subsequent releases. FMS can store, load, transfer and unload pallets automatically and reduce multiple operations to a single run. This provides massive benefits when it comes to lot consistency, lead time, and cost.

With horizontal machining centers from 400mm to 800mm, we have huge range on the size of part we can accommodate.

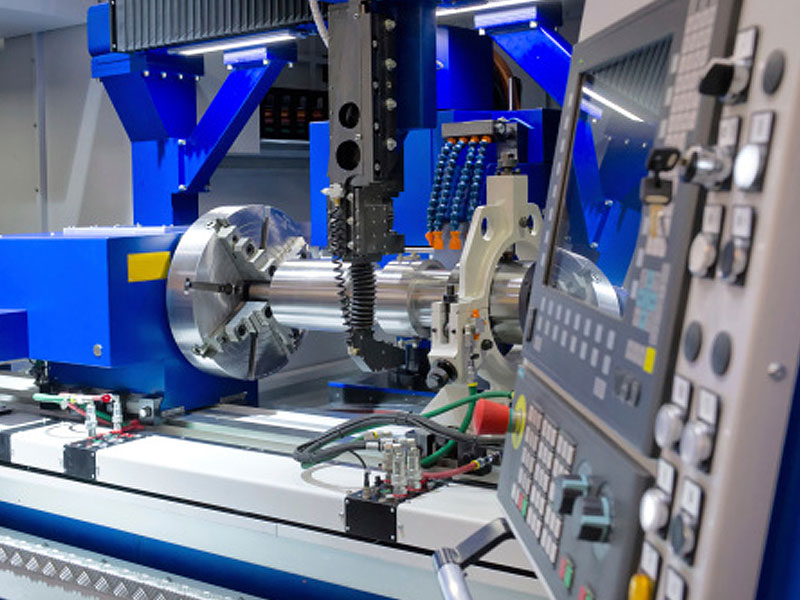

CNC turning and milling

We have state of the art turning systems from Mazak and Mori Seiki, and high production, auto-loaded four spindle chucking equipment from Shimada. Our lathes are always paired with a 4-axis vertical machining center or live tools to assure a complete part in one cellular operation.

See the complete list of our CNC turning and milling equipment »

Thermal deburring

Our ATL iTem 400/600 is the first Thermal Deburring System of its type in the country. With a chamber measuring 400MM in diameter and 600MM tall, we can deburr a full chamber of parts in five minutes.

We specialize in Hydraulic manifolds, often with hundreds of features. Like most Machining Facilities, we use to rely on our team to remove burrs by hand. In some cases, this imperfect process would take hours, and chances are, need rework.

By utilizing this process, we can get more done with fewer operators, and we never miss a burr. Watch the video to see how it works!

Industries served

Industries Served:

Defense • Motorcycle • Hydraulic Components • Agriculture • Aerospace • Heavy Equipment

Locations:

Jefferson, WI Location

211 Collins Road

Jefferson, WI

920-674-6003

Your Solutions

We are...

State-of-the-art

Our proprietary software, Total Tool Maintenance TM™ (TTM™), Automation in Manufacturing™ (AIM™), and Scheduling System provide the data and information we need to produce quality parts, on-time.

We are...

Working smarter, not just harder

Our Horizontal Machining Center capacity has been expanded with the addition of a Mazak Palletech Flexible Manufacturing System (FMS). One of the largest in the country, our system offers 6 500MM Horizontal Machining Centers, 120 pallets, and 348 tools per machine. We can now produce any mix of complex parts with zero setup.

We are...

Innovative

- Our teams have the resources to meet customer needs.

- FMS automation reduces setups and maximizes utilization.

- Thermal deburring processes for 100% burr free product.

- Coordinate measuring machines and a fully networked facility help teams quickly gather relevant, accurate information

© 2025 Basin Precision Machining • Privacy Statement • Terms of Use • Site Design: D2P Web Design

Jefferson, WI Location • Basin Precision Machining • 211 Collins Road • Jefferson, WI • 920-674-6003